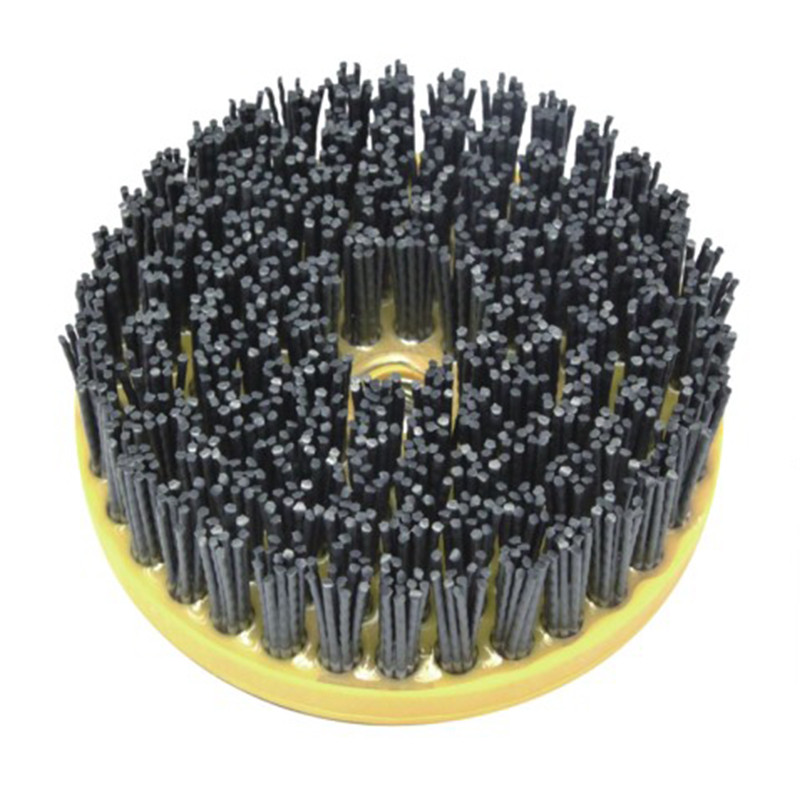

Round Silicon Carbide Abrasive Brush |Abrasive Brush For Marble Polishing | Customizable Abrasive Filament Brushes

Item specifics

- Base Material

- PA 612, PA 610 or PA 6

- Grinding Coumpound

- Silicon carbide

- Grinding Coumpound

- Marble, travertine, artificial stone, etc

- Handle Material

- Plastic

- Brush Head Size

- 6,500

- Max RPM

- 6,500

- Speed Rating

- Level 1

- Bristle density

- 10/Number of Bristles per Unit Area

- Bristle length

- Customizable

- Surface Finish

- Making Leather, Laptop and Lapatura Finish

Review

Description

Introduction to Round Silicon Carbide Abrasive Brush

Round Silicon Carbide Abrasive Brush

Silicon carbide abrasive brush is a commonly used surface treatment tool that uses silicon carbide particles as abrasives to remove surface oxides, rust spots, dirt, etc. by wiping the surface of the workpiece with a rotating brush. It has the characteristics of high grinding efficiency, long service life, convenient use, and good treatment effect, and is widely used in the grinding and polishing treatment of surfaces of materials such as metals, ceramics, plastics, rubber, etc.

Main Feature:

1. High hardness and wear resistance: Silicon carbide particles are a very hard material that is harder than most other abrasives, so silicon carbide abrasive brushes have excellent wear resistance and can maintain good wear performance in high load and high-speed grinding.

2. Efficient grinding: The high hardness and wear resistance of the silicon carbide abrasive brush give it efficient grinding ability, which can quickly and effectively remove surface problems such as dirt, rust spots, and oxides. More importantly, it can improve the grinding speed while maintaining good surface quality.

3. Long lifespan: Due to the hardness and wear resistance of silicon carbide materials, silicon carbide abrasive brushes have a longer service life, which can better extend product life and reduce process costs compared to other grinding tools.

4. No static electricity generation: Silicon carbide abrasive brushes are less likely to generate static electricity, which is crucial for handling flammable materials and can effectively reduce the risk of fire and explosion in the workplace.

5. Easy to operate: The structure design of the silicon carbide abrasive brush is compact, lightweight, and easy to operate. It is suitable for various surface shapes and sizes of workpieces, and can adapt to different working environments and special workpiece processing needs.

Round Silicon Carbide Abrasive Brush Specifications

Tags: | Content | |

|

Type:

|

Round Silicon Carbide Abrasive Brush

|

|

|

Grit:

|

30#, 40#, 46#, 60#, 80#, 120#, 180#, 220#, 400#, 500#

|

|

|

Application:

|

Making leather, laptop and lapatura finish or granite, marble, artifical stone surface.

|

|

Additional information

Operating Recommended Speed

Optimum performance is obtained at the recommended working speed 2.500 R.P.M.

Speeds above the recommended ones may smear the workpiece due to heat build-up.

FAQ

1.What surface treatments are your Round Silicon Carbide Abrasive Brush for?

Our abrasive brushes can be used for polishing stone, wood, metal, and more. Based on your specific applications, we can recommend different brush styles and bristle materials.

2.What are the advantages of our Round Silicon Carbide Abrasive Brush to competitors?

Excellent heat resistance, adaptable to various climate conditions, and versatile in application. Outstanding bending recovery capability, high tensile strength, and excellent fatigue resistance. It possesses good resistance to acids, alkalis, and other chemicals.

3.Is it possible to customize abrasive brushes to specific specifications or designs?

Yes, in addition to our standard Frankfurt, Fickert, and Round abrasive brushes, we can customize abrasive brushes to specific specifications or designs according to your requirements.